At JD Fowles & Partners in Frodsham, Cheshire, slurry management has always been a crucial for maintaining a productive dairy operation. With 230 cows across breeds like Holstein Friesian, Danish Red, and Brown Swiss, the farm generates substantial volumes of slurry. Much of this slurry is influenced by straw bedding, resulting in a tendency to float and form a thick crust.

Tom Fowles, who helps manage the farm, recently began trialling Maneuver® Lagoon, a slurry additive designed to break down solids, reduce crusting, and improve overall slurry management. “We’re trialling the Maneuver Lagoon and seeing whether we can improve our soils and slurry,” says Tom.

The Problem: Crusting from Straw Bedding

Crusting has been a long-standing challenge for many farmers, and Tom’s farm is no exception. With chopped straw used as bedding, the slurry store is prone to forming a thick crust on top. Tom had experimented with several slurry additives in the past, but he found that these products failed to deliver results.

“We’ve used an additive in the past, we didn’t find it to actually have any effect. It just seemed to sound good but didn’t really do a lot at all,” Tom recalls.

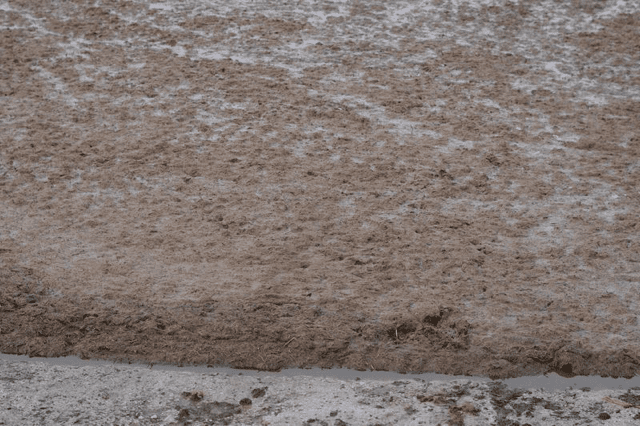

The primary concern for the farm was the crust that formed due to the chopped straw bedding. “The slurry issue is crusting because we’re bedding on chopped straw, so obviously that floats to the top and we end up having a real good thick crust over the lagoon,” he explains.

This crust wasn’t just a visual nuisance; it had significant operational consequences. The thick, stubborn crust slowed down the slurry mixing process, making it a labour-intensive job. On a busy farm like JD Fowles & Partners, mixing the slurry could take up to three hours, time that could be better spent on other tasks.

Using Maneuver Lagoon: Simple to Apply

Eager to address the issue, Tom quickly integrated Maneuver® Lagoon into the farm’s slurry management routine. He found the product easy to apply, and it fit seamlessly into the existing schedule.

“Pretty simple really, it’s more the thing of remembering to do it – remembering to mix it, to put it in the slats and put it in the lagoon. But as soon as you’re in the cycle of doing it, it’s easy to use, it takes five minutes,” says Tom.

Maneuver® Lagoon can be applied through the slats or directly into the lagoon. This slurry additive contains a mix of naturally occurring bacteria, such as Bacillus licheniformis, Bacillus subtilis, and Enterococcus faecium. These bacteria work together to break down solids in the slurry and help prevent the formation of a thick crust. Additionally, the product helps retain more nitrogen in the slurry, improving its value as a fertiliser for the farm.

Initially, the product worked to liquefy the slurry underneath, but the top layer of crust remained in place for some time. However, it wasn’t until Tom, who operates in a Nitrate Vulnerable Zone (NVZ), mixed the lagoon in preparation for spreading that he noticed a clear difference

“Visually, the crust has been a lot softer, half the thickness, but a lot softer. It’s easily breaking up this time. A lot foamier than normal. It normally does foam a little with water, but it’s a lot thicker of a foam,” says Tom.

Real Impact: Less Time Spent Mixing

Before trialling Maneuver® Lagoon, mixing the slurry could take anywhere from two to three hours. But after using this slurry additive, the results were immediate and undeniable. The time required to mix the slurry dropped dramatically to just 1 hour and 7 minutes, representing a 55% time saving.

This reduction in time spent on mixing not only freed up valuable time for other tasks but also translated into fuel savings and reduced equipment wear and tear. With less time on the tractor, the farm also reduced diesel usage, adding to the overall efficiency of operations.

For Tom and his team, the time saved meant more flexibility in their daily routine. They could now focus on other critical farm tasks, knowing that slurry management wouldn’t consume their entire day. This allowed them to optimise their workflow and allocate more time to other important aspects of farm management.

Early Signs, Promising Results from Maneuver Lagoon

For farmers facing similar challenges with crusting and long mixing times, Tom’s experience serves as a valuable case study. His results show how small changes in slurry management, such as incorporating the right slurry additive, can lead to significant time and operational savings.

Tom’s experience with Maneuver® Lagoon, a Novonesis product, highlights how effective it can be in improving slurry management. It’s a reminder that, sometimes, the right solution at the right time can make all the difference in running a more efficient farm.