SILOSOLVE® FC

Good silage shouldn’t be an accident

The key to preserving silage is the removal of oxygen from the clamp. SiloSolve FC works differently to other inoculants by removing oxgyen in a matter of hours, saving valuable nutrients and cutting damaging aerobic organisms off. This kickstarts the fermentation process in the right direction, on all conventional crop types.

Key Features and Benefits:

Early opening, after just 7 days

For use on all conventional crop types and dry matters

- Improved palatability – meaning more productivity (more milk/meat)

L. lactis 0224 removes oxygen in just a few hours, inhibiting up to 98% of yeasts & moulds

L. buchneri (unique to SiloSolve FC) produces acetic acid to eliminate spoilage organisms

Inhibits mycotoxin production

Improved dry matter retention

Less waste (and less throwing away expensive TMR)

What's Inside SILOSOLVE FC?

These strains are unique to SiloSolve and not available in any other inoculant.

The key to this new way of preserving silage is the removal of oxygen from the clamp.

Lactococcus lactis (O-224) rapidly removes oxygen from the clamp, a process that takes only 6 hours! The silage fermentation is stabilized very quickly with a low level of lactic acid and the oxygen removal makes sure that the spoilage organisms, yeasts and moulds, are unable to grow.

The second bacteria in SiloSolve FC, Lactobacillus buchneri (1819), produces acetic acid to eliminate any remaining yeasts and moulds, protecting the feed value in the forage meaning more energy and protein available for milk or meat production.

The combined effects from these two bacteria mean that the silage rapidly stabilises and the clamp can be opened and fed in just 7 days!

Watch this quick video to see exactly why it’s so different to other silage inoculants.

Not convinced? Here’s the science:

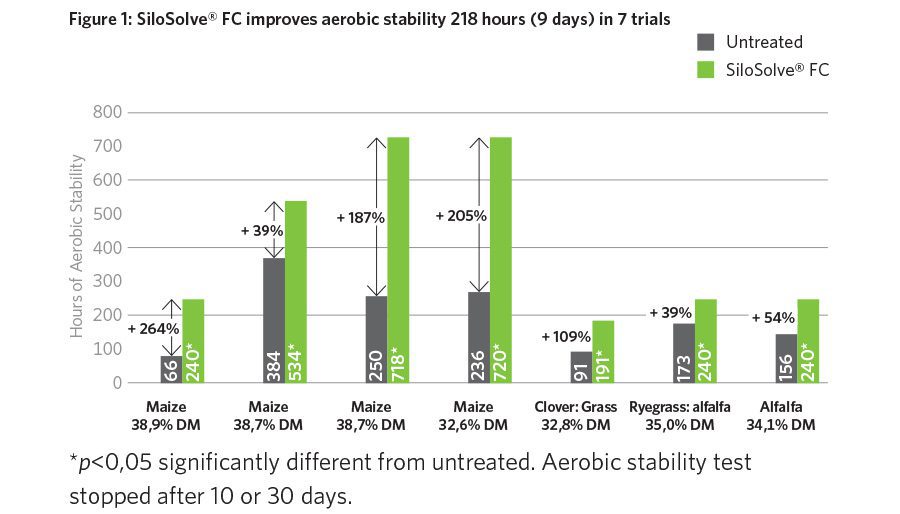

SILOSOLVE® FC improves aerobic stability while improving dry matter recovery

SILOSOLVE® FC is a unique, dual-action inoculant that improves aerobic stability and at the same time improves dry matter recovery over a broad range of dry matter and forages. While SILOSOLVE® FC increased aerobic stability up to 30 days in university trials, dry matter recovery across crops was improved an average of 3.5% points compared to untreated silages.

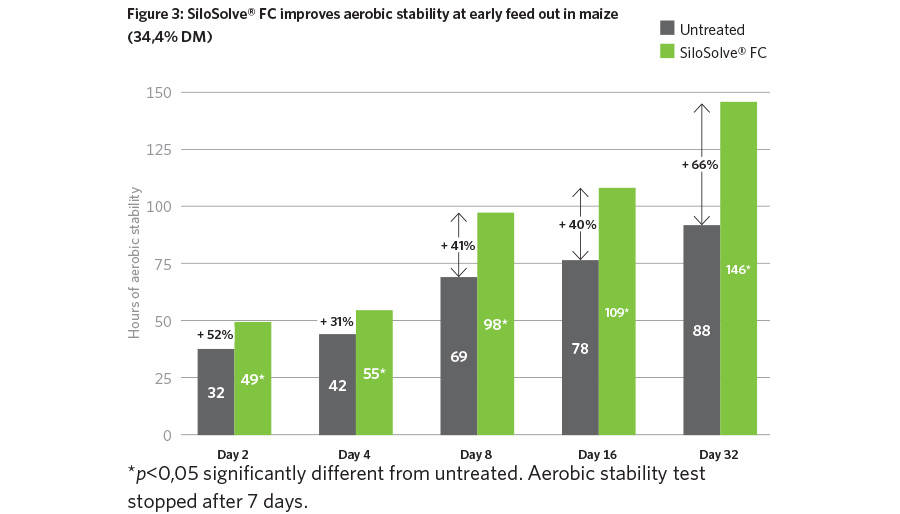

SILOSOLVE® FC improves stability – even at early feed out

Review of the literature indicates that L. buchneri normally produces acetic acid after 56 days of ensiling. With SILOSOLVE® FC, acetic acid production has been observed on day 2 of ensiling maize silage and as a result improved aerobic stability even after a short fermentation time. In alfalfa silage aerobic stability was improved by 13 days.