SILOSOLVE® MC

Good silage shouldn’t be an accident

We all like the weather conditions to be perfect when making silage., unfortunately, we also know that we can’t rely on the Great British Summer and we need an inoculant that can deal with the challenges when ensiling conditions are less than perfect.

Key Features and Benefits:

- Inhibits clostridial bacteria (soil & slurry contamination)

- Reduces ammonia by up to 50%

- Improved productivity

- Improves aerobic stability.

- Reduces waste dramatically.

What's Inside SILOSOLVE MC?

SiloSolve MC addresses problems via it’s unique formulation, it contains three strains of bacteria, all unique to Chr. Hansen:

L. plantarum (CH 6072) and E.faecium (DSM 22502) deliver a rapid, controlled production of lactic acid to quickly lower the pH. and inhibit the growth of undesirable bacteria.

The final, and most important organism is Lactococcus lactis (SR3.54)

This strain of L.lactis is a “hunter killer” of Clostridia and other spoilage organisms and even has a patent for clostridia control.

No producer wants to feed his livestock on forage that contains Clostridia and SiloSolve MC has been proven to dramatically lower Clostridia numbers when ensiling conditions are difficult.

Watch this quick video to see exactly why it’s so different to other silage inoculants.

Not convinced? Here’s the science:

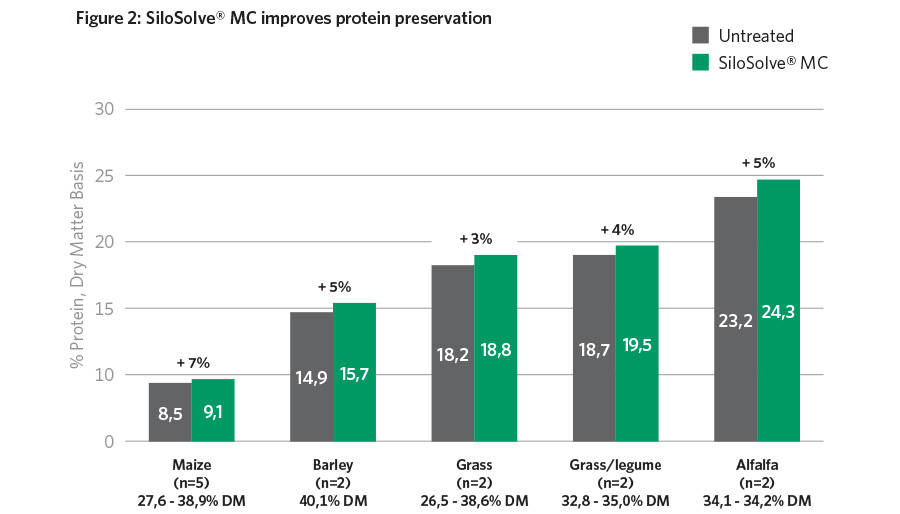

SILOSOLVE® MC reduces protein degradation & reduces ammonia

Ammonia is an indicator of protein breakdown and may lead to reduced intake by dairy cows. In high value crops, like alfalfa and grass/legume mixes, SILOSOLVE® MC reduces ammonia up to 50% and improves protein preservation up to 5% compared to untreated silages. The benefits are higher quality silage with less feed refusal.

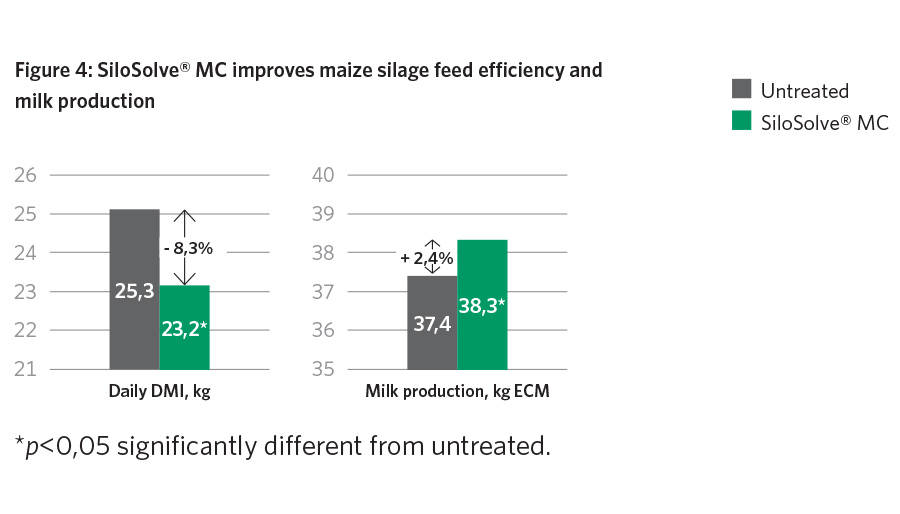

SILOSOLVE® MC improves fermentation leading to increased milk production

SILOSOLVE® MC consistently improves fermentation which leads to a significant increase in milk production. Cows fed SILOSOLVE® MC treated maize silage had increased efficiency of milk production through an 8% reduction in dry matter intake and a 2% increase in energy corrected milk yield. A similar response was observed in cows fed SILOSOLVE® MC treated alfalfa.